Showroom

Below you can see some of the examples, which are prototypes that are used during product development. Whether in plastic, rubber or a 2K-part, there are many opportunities to see the product before starting up a production run.

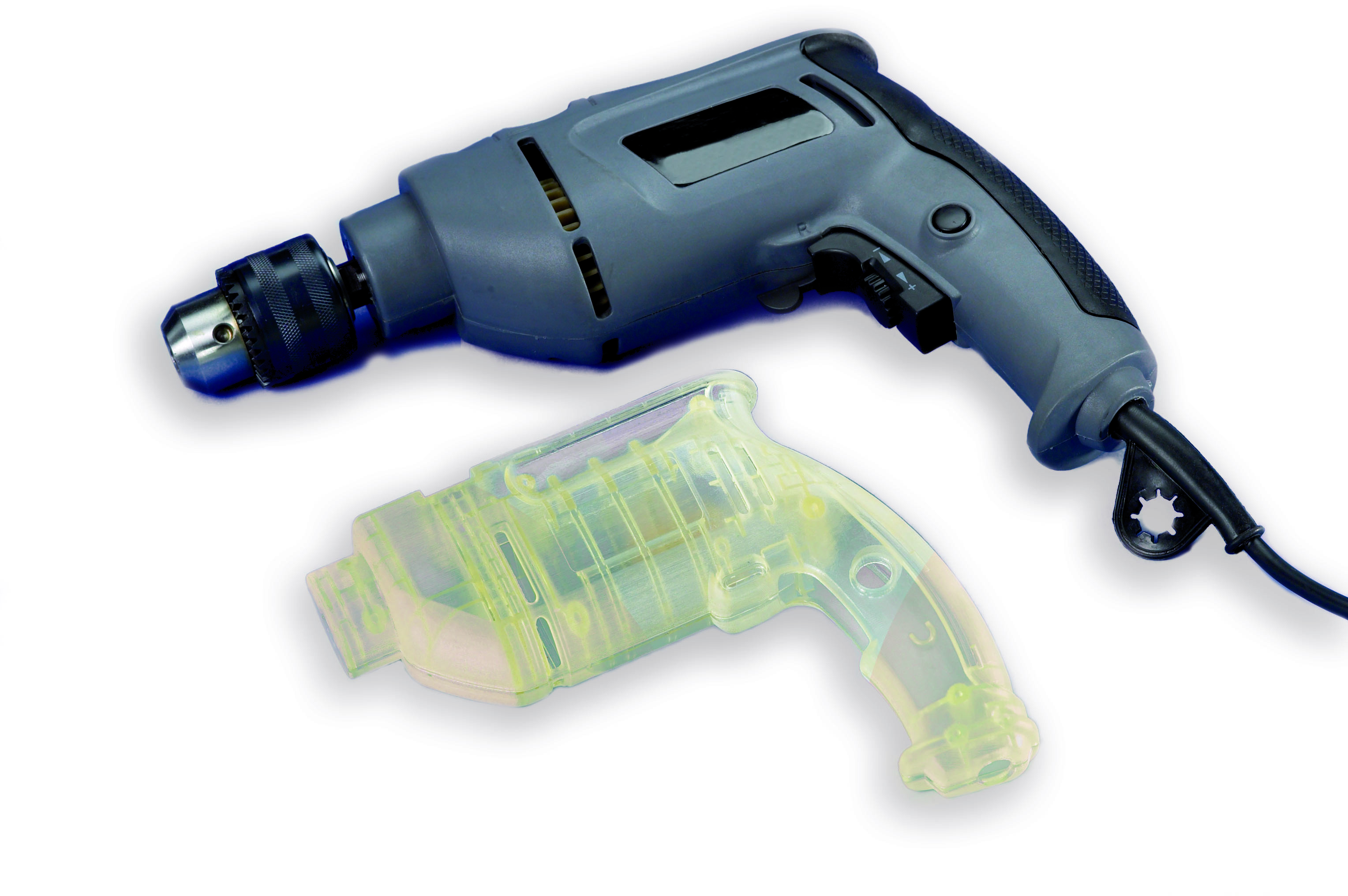

Standard Plastic and Rubber parts

It is possible to check whether there is room for all the components in the assembly process through the use of transparent shells.

Design assessment of silicone dish, functionality and design.

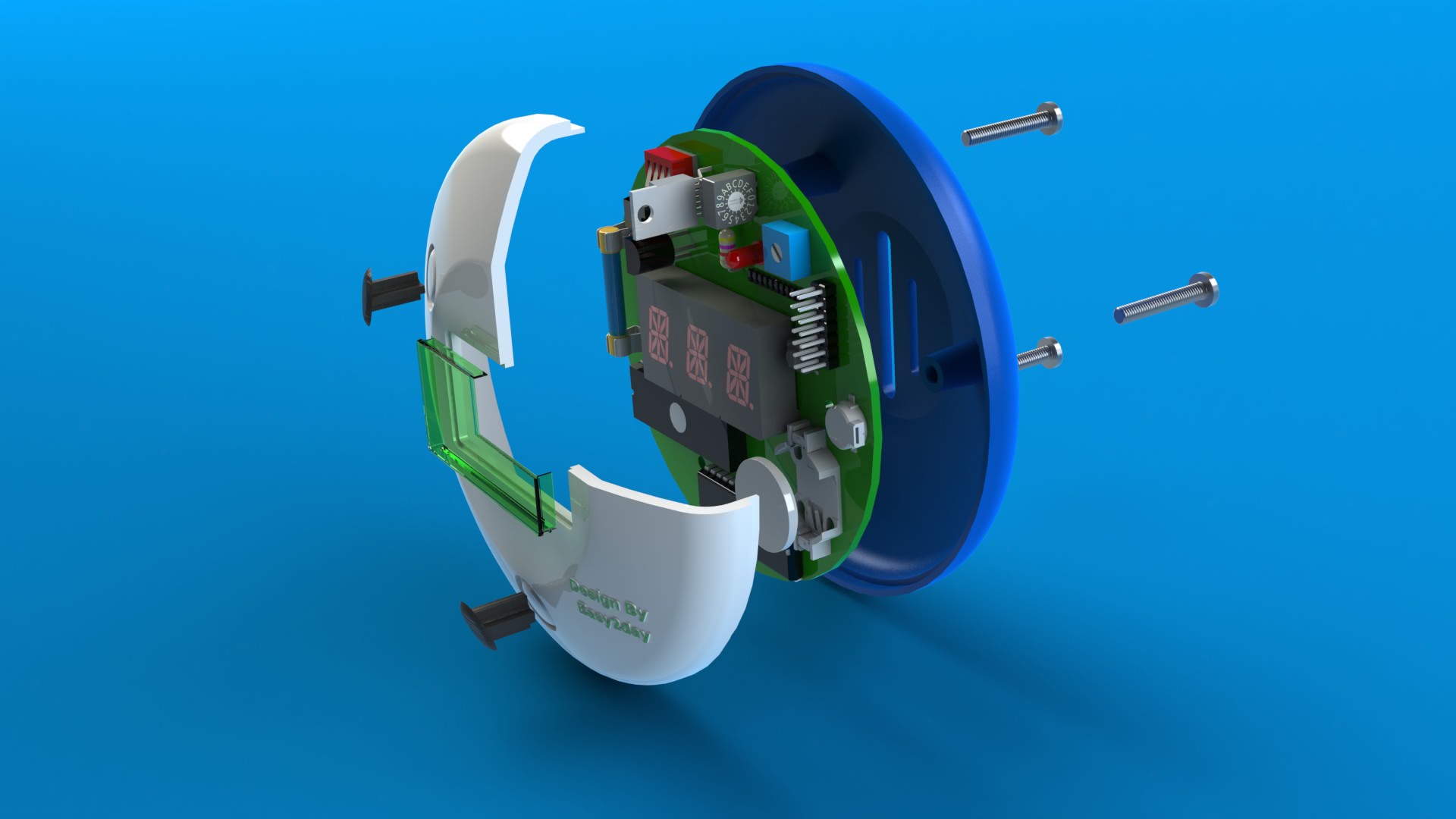

2K - Parts

Remote control for testing fit and feel of buttons. The part is printed in one continuous operation.

Toothbrush with soft hair which is printed in one operation for testing.

With digital materials it is possible to look at the handle and see if it feels right to the touch.

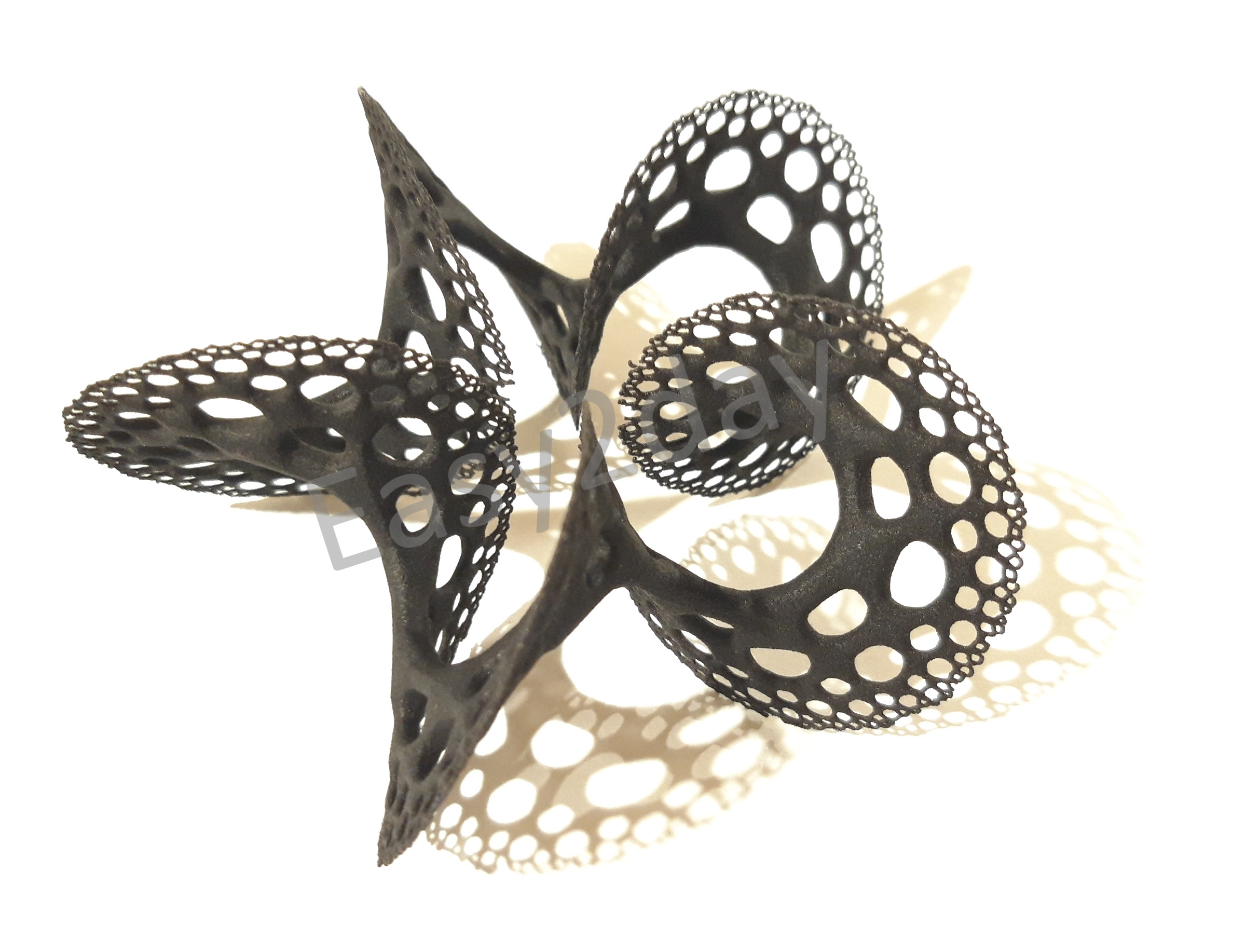

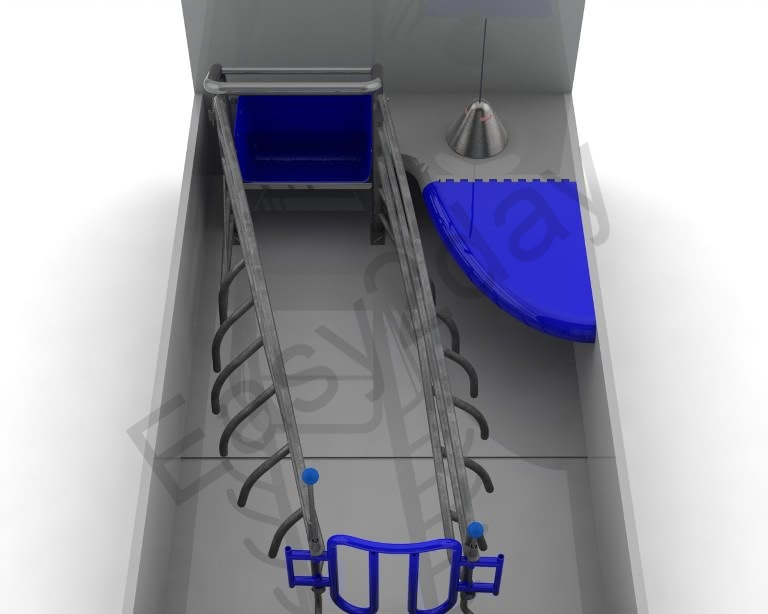

For research and medical use

It is possible assess how to position the implant in the patient.

Head of a bat scanned and constructed as a prototype, for use in studio experiments of sonar.